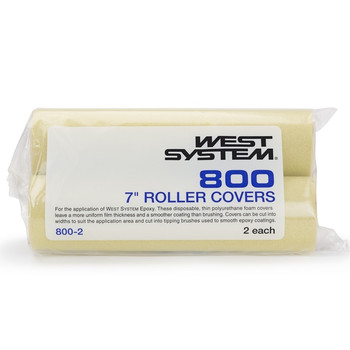

Description

Heavy duty, flexible plastic roller pan allows you to “pop out” epoxy after it has cured so the pan can be re-used. Eliminates the need for pan liners when working with epoxy.

Increase epoxy’s working time with an 802 Roller Pan

Epoxy cures by a chemical reaction between the resin and hardener that releases heat, called an exothermic reaction. The larger the volume of epoxy the more heat that is generated. Many epoxy users have seen pots of epoxy uncontrollably exotherm. The good news is there are some things you can do to prevent this, and using a roller pan is one of them.

A good rule of thumb for gauging cure speed is that for every 18°F increase above 72°F, the working time and pot life will be cut in half. To maximize the working time of the epoxy, consider how much time you need and what temperature you’ll be working at, then select the hardener accordingly.

The pot life on the WEST SYSTEM technical data sheets refers to a confined mass of 100 grams of epoxy at 72°F. Pot life is always shorter than working time because epoxy contained in a pot kicks off faster than epoxy spread into a roller pan (thin film). Spreading out the epoxy extends working time. Select either the 206 Slow or 209 Extra Slow Hardener for best results in warm temperatures.

After thoroughly mixing resin and hardener, pour the epoxy into roller pans (or onto the substrate you plan to coat). This will increase the surface area so the epoxy’s heat buildup (exotherm) can dissipate, slowing the reaction and extending your working time.

Further cooling in hot weather

Foam box holding water and an 802 Roller Pan to help cool epoxy and increase working time in hot temperatures

Foam box holding water and an 802 Roller Pan to help cool epoxy and increase working time in hot temperatures

To slow epoxy’s reaction in very warm temperatures, create a simple foam box that is glued together and sealed to hold your roller pan. Fill the inside of the foam box with tap water that will act as a heat sink and increase epoxy’s working time. An ice cube or two can be added as long as you do not chill the epoxy too much. Chilling the epoxy too much can cause moisture in the air to condense on the epoxy. Excess moisture can cause the epoxy to cure at a faster rate, become cloudy, and reduce its cured physical properties.

Warranty Information

Specs

UPC: |

10811343012028 |

|

MPN:

|

802

|